Modular Integrated Training System Microcontroller

- Supports multiform MCU of independent module structure

- Supports CPLD module for digital circuit experiment

- Functional modularity of application

- Provides analysis and measurement module for improving the efficiency of MCU learning

- Supports various interfaces for signal connections between MCU and module

- Offers measurement point for signal analysis

- Provides multiform program experiments for the basis and project experiments

Introduction

MCU products based on 8-bits is the basic training theme that is being used on education sites for a long time. However, when it is a product manufactured to fit into traditional training method, a cramming one, it is impossible to configure its capabilities in the way users want, This product is a micro embedded training system designed to support variety of MCUs and, based on that, realize independent modularity of each function for the purpose of quickly applying the multiform program lessons including the basic training and meeting user’s requirements to effectively apply the creativity engineering training recently emerging from universities and high schools to education.

Features

- Devices of ATmega128, 89C51, PIC18F6722 designed to be modules of connector structure which are mountable and removable, allowing multiform microcontroller training.

- CPLD module installed to perform the digital circuit design education at the same time.

Provides a configuration that multiform connects MCU module and functional module. - Each functional module can be installed and removed so users can use application design type they want by utilizing functional modules separated from the base board user wants.

- Provides the signal and power analysis modules that can improve the efficiency of MCU lesson and design.(interrupt, frequency analysis)

- Provides the dedicated measurement point for easy analysis of MCU and application signals.

- Provides multiform input switches and output display devices.

- Multiform sensor modules are mountable.

- Provides application modules for USN and sensor training.

- Provides various experiment programs necessary for application experiment.

- Supports multiform design environment ranging from the basic processor education level to the application design level.

- Provides multiform option modules such as stack module and actuator module for maximizing use of the product.

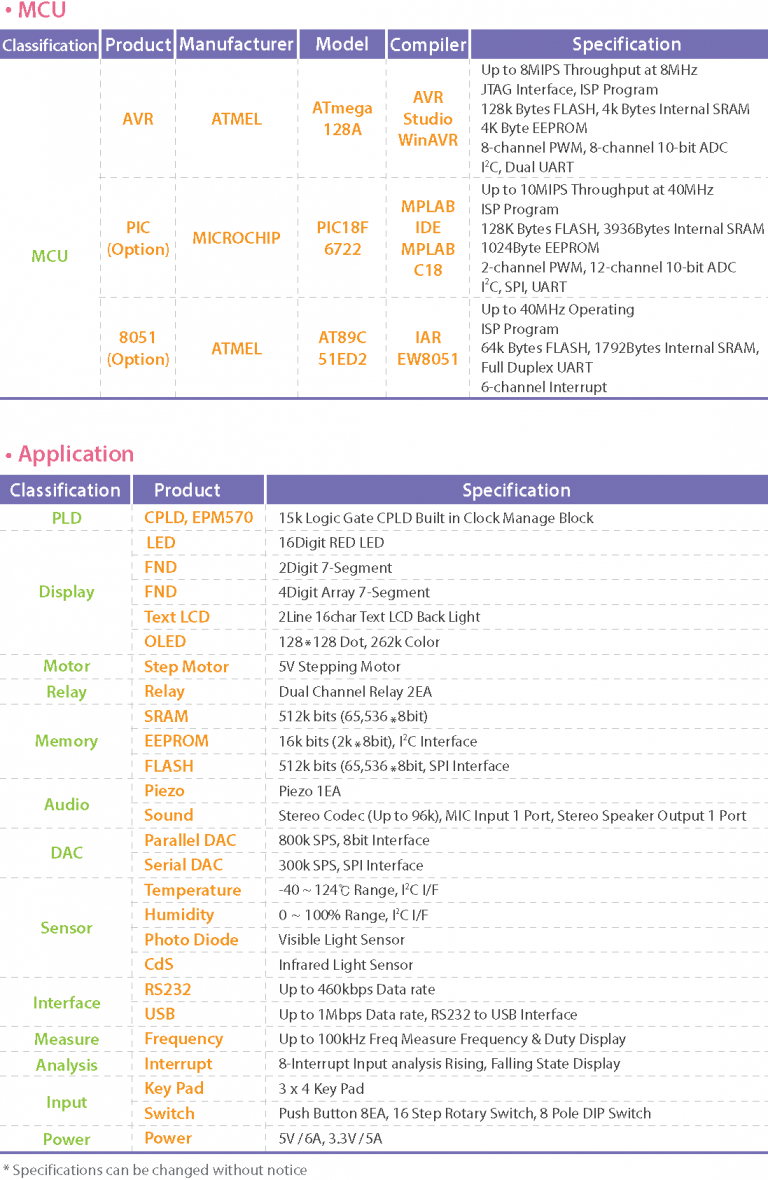

Product Specifications

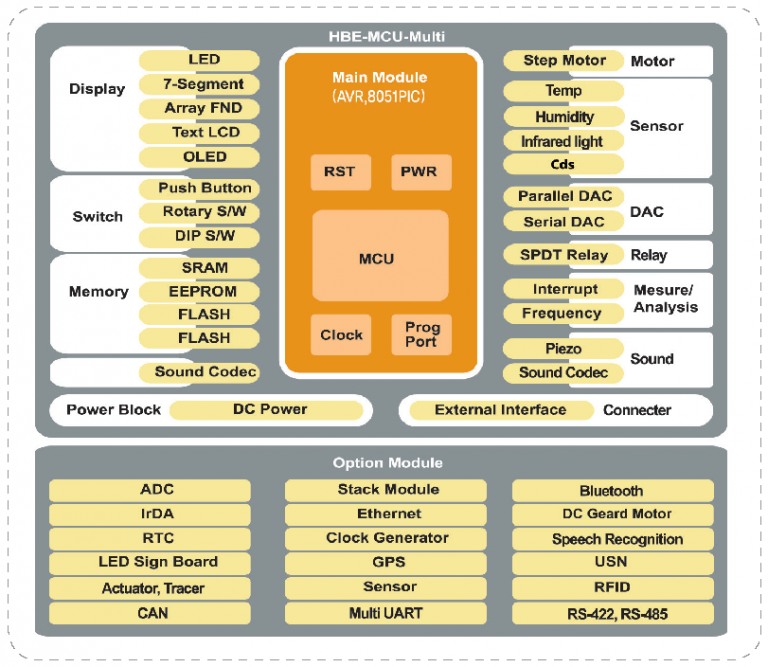

Block diagram

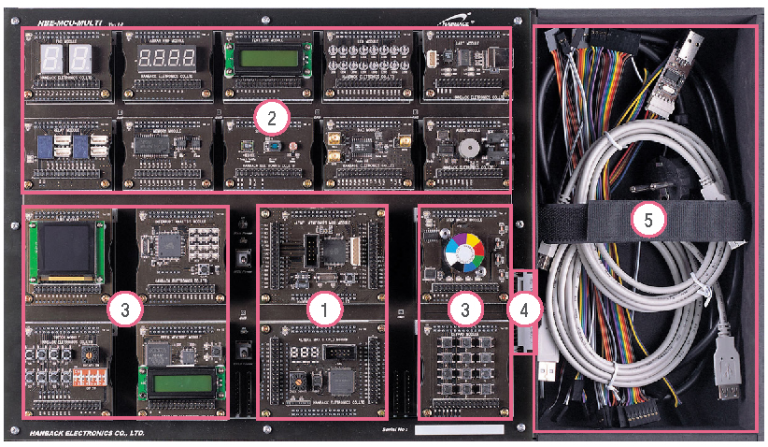

Main configuration

1. MCU Module Zone : MCU and CPLD Module

2. 56mm *45mm Module Zone : LED, FND, Array FND, Text LCD, Sensor, Memory, Relay, DAC, Audio, UART Module

3. 56mm *60mm Module Zone : OLED, Step Motor, Switch, Key Pad, Freq Measure, Interrupt Analysis Module Installation

4. Option Module Interface : Interface for connecting option modules additionally provided

5. Cable box : Contains various cables used for the product

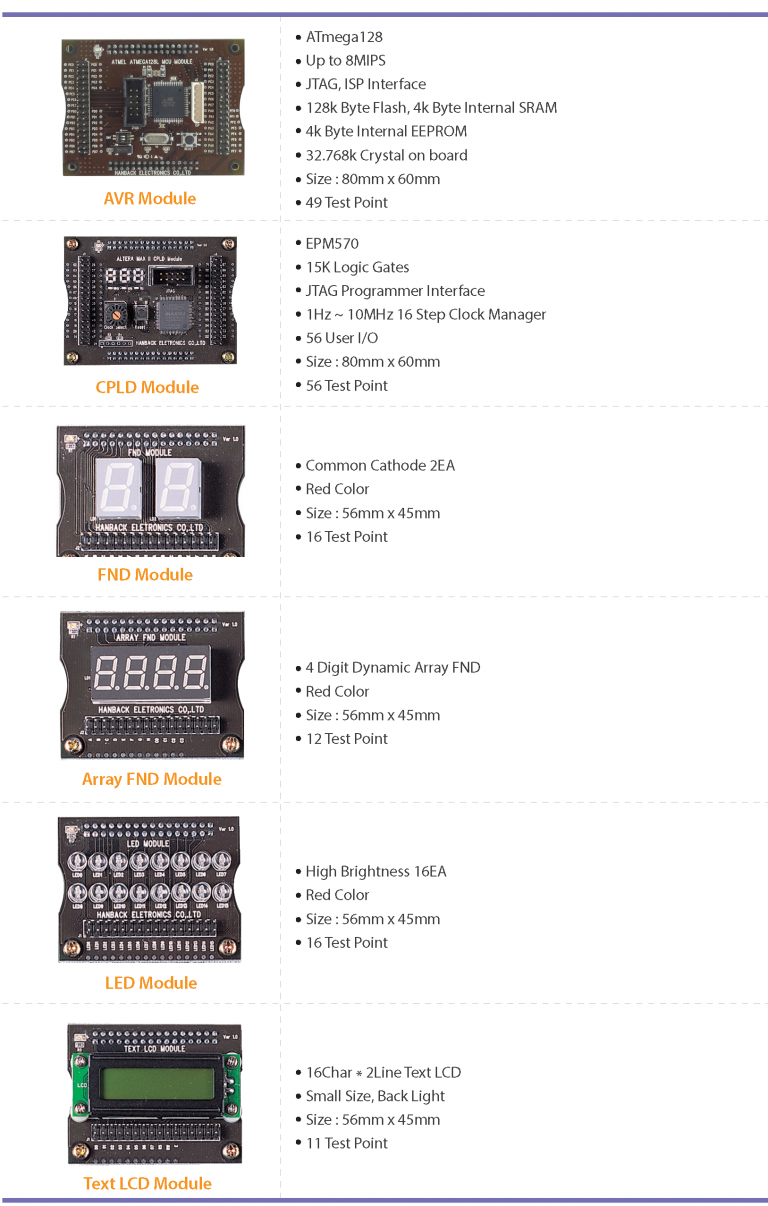

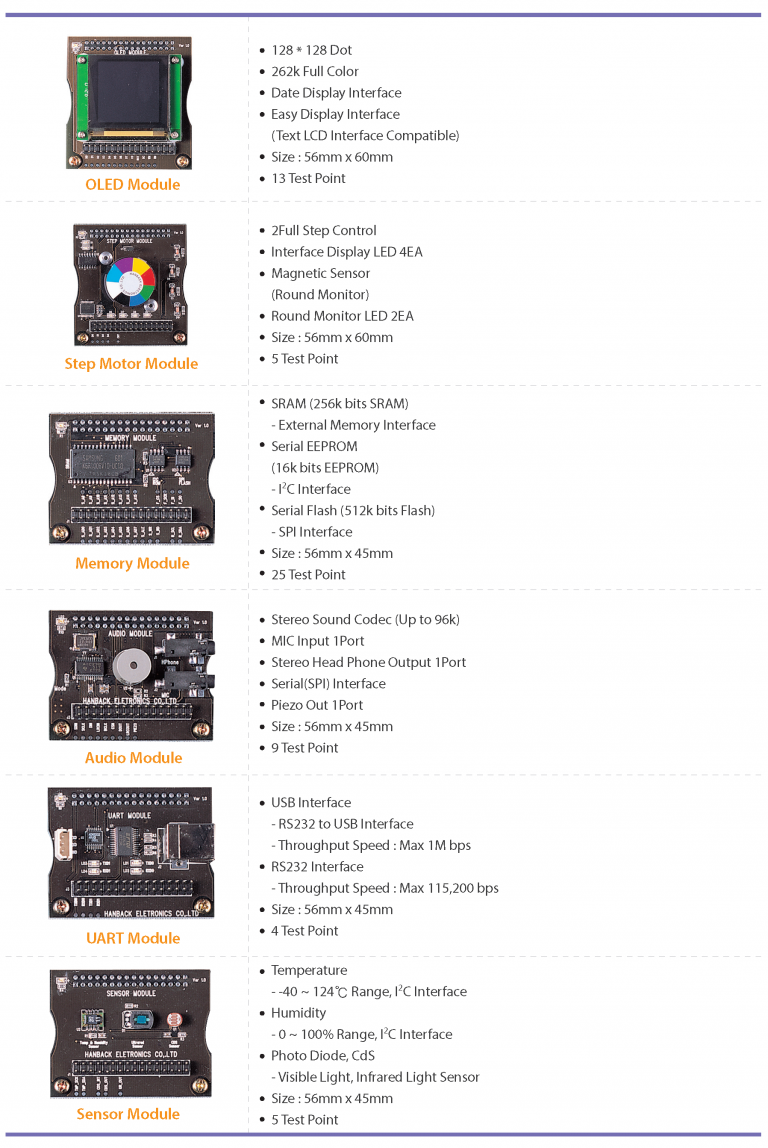

Module Specifications

Basic Modules

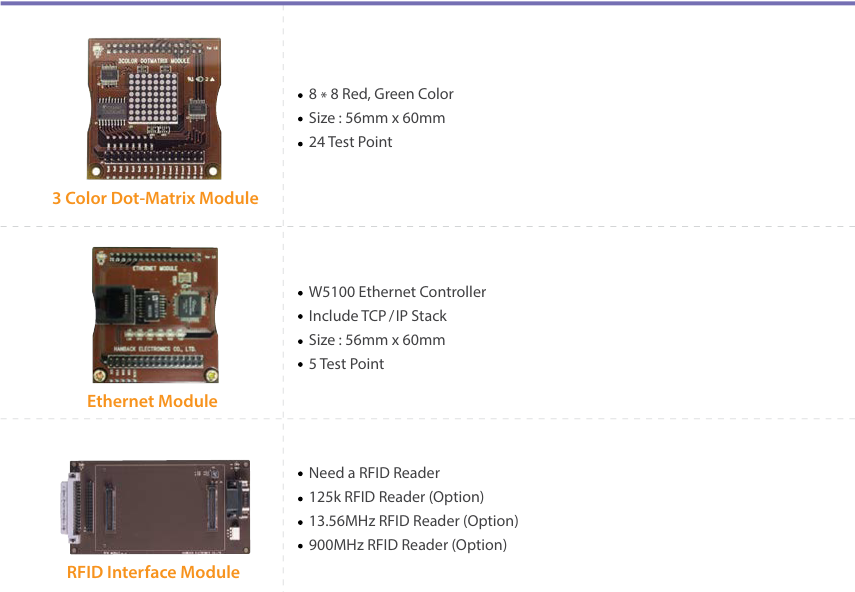

Option Modules

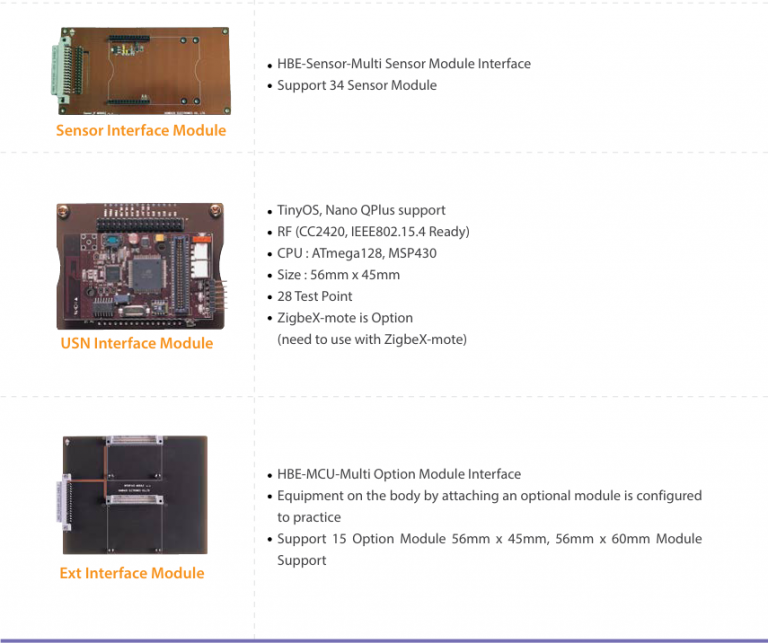

Application Modules (Option)

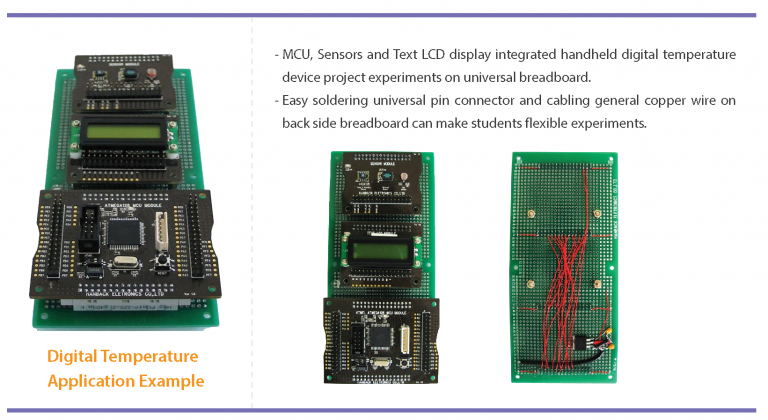

Application Examples

All kinds of modules of HBE-MCU-Multi can be used for the application of universal breadboard.

Training Contents

HBE-MCU-Multi(AVR)

OVERIEW OF MICROCONTROLLER

1. AVR Micro Controller

2. AVR Micro Controller Development Environment

FUNCTIONS OF MICROCONTROLLER

3. GPIO I/O Control

4. Internal Memory

5. Interrupt

6. Timer and Counter

7. Timer and PWM

8. UART

9. A/D Converter

10. External Memory Interface

11. Serial Interface

USING MICROCONTROLLER

12. Rotating Step Motor

13. Pin Pad using KeyPAD

14. LED brightness control using DAC function

15. Digital frame using OLED

HBE-MCU-Multi(8051)

OVERVIEW OF MICROCONTROLLER

1. 8051 Micro Controller

2. 8051 Micro Controller Developing Environment

FUNCTIONS OF MICROCONTROLLER

3. GPIO I/O Control

4. Internal Memory

5. Timer and Counter

6. Interrupt

7. PCA and PWM

8. UART

9. External Memory Interface

10. Serial Interface

USING MICROCONTROLLER

11. Rotating Step Motor

12. Pin Pad using KeyPAD

13. Controlling LED brightness with DAC

14. Make Paint with OLED

HBE-MCU-Multi(PIC)

1. PREPARING TEST AND USING MPLAB

2. TURNING ON LED

3. RECEIVING PORT INPUT

4. STATIC FND

5. DYNAMIC FND

6. INPUTTING SEVERAL SWITCHES(KEYPAD)

7. DISPLAYING CHARACTERS ON TEXT LCD

8. RECEIVING EXTERNAL INPUT OF TIMER/COUNTER

9. INTERRUPT

10. STEPPING MOTOR

11. PWM

12. UART COMMUNICATION

13. ADC

14. EEPROM

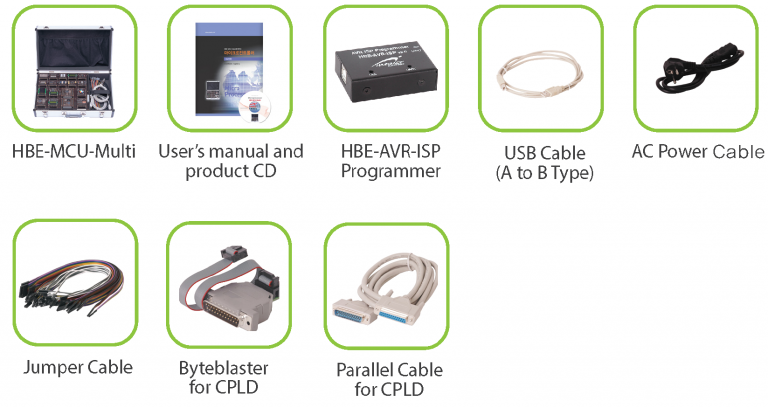

Product Configuration